The small diamond ball that can help dream about the near-infinite clean energy

4 min read

- author, Carrie King

- roll, from Berlin

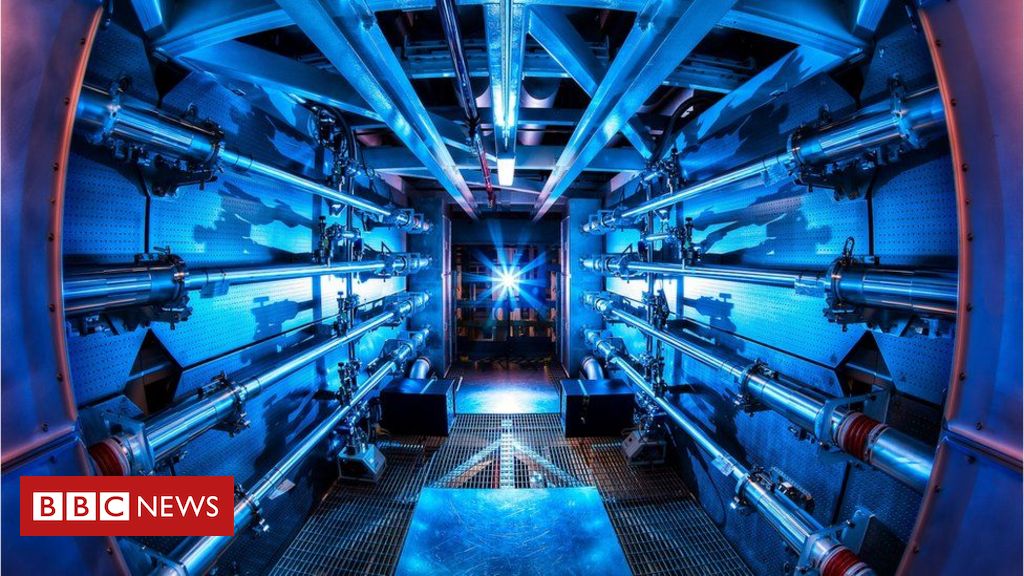

credit, Lawrence Livermore National Laboratory

The National Ignition Facility in California is home to the most powerful laser in the world

At 1:03 a.m. on Monday, December 5, scientists at the National Ignition Facility in California directed 192-beam lasers at a cylinder containing a small diamond fuel capsule.

This powerful burst of laser light created enormous temperatures and pressures and triggered a fusion reaction – the reaction that powers the sun.

The National Ignition Facility (NIF), part of Lawrence Livermore National Laboratory (LLNL), has conducted such experiments before, but this time the energy generated by the reaction was greater than that of the laser used to activate it.

Scientists have been trying to get this far for decades, and the hope is to one day build power plants that use the fusion reaction to generate abundant, carbon-free electricity.

This result is still some way off, and in the meantime, there is a lot of work to be done in developing the technology.

credit, Lawrence Livermore National Laboratory

The development of the fuel capsule took decades of work.

One of the main components of NIF is a synthetic pepper-sized diamond capsule that contains the fuel.

The properties of this spherical capsule are essential to creating a successful fusion experiment.

The ball must be completely smooth and free of contamination – any anomaly can put an end to the experiment.

These precision engineered balls are not made in California. It is the result of years of work by Diamond Materials, a company based in Freiburg, Germany.

Demand for capsules [esféricas] Too high,” says Christoph Wild who, along with Eckhard Werner, is Managing Director of Diamond Materials.

“We work closely with Lawrence Livermore and try to minimize defects such as blemishes, cavities or uneven walls.”

Diamond Materials’ team of 25 manufactures synthetic diamonds through a process called chemical vapor deposition.

credit, Lawrence Livermore National Laboratory

The surface of the fuel capsule must be completely smooth.

From start to finish

It takes about two months to create each batch of 20 to 40 capsules, which are made by precisely placing tiny diamond crystals around a silicon carbide core and polishing it repeatedly.

During the development process, they found that even the most careful polishing was not enough, because on a microscopic level, the surface was still bumpy and uneven.

Working with teams at LLNL, they finally discovered they could coat a polished capsule with a new layer of diamond crystals to get the clean mirror finish they needed.

When the diamond capsules reach LLNL, the silicon core is removed and a small glass tube is used to fill the hollow sphere with deuterium and tritium, both heavy forms of hydrogen, which fuel the fusion reaction.

“The pellet fuel is surrounded by a cylinder of gold and weak uranium,” explains Mike Farrell, vice president of inertial fusion technology at General Atomics, LLNL’s largest industrial partner.

The third and final layer of the capsule is an aluminum cylinder used to cool the contents of the capsule before the reaction.

Another important area of technology at NIF is optics—anything that supports the transmission, detection, or use of light.

Because NIF operates the most powerful laser in the world, it uses too much of this technology and the optical components are damaged every time the device is turned on.

credit, Lawrence Livermore National Laboratory

The development of optical technology will be key to the future of laser-based fusion

Since the early 1970s, NIF has worked closely with optics manufacturers such as Zygo Corporation and specialty glass manufacturer SCHOTT to install and supply replacement parts, as well as wreck and blast shields.

After December’s successful experiment, the next challenge for NIF and its partners will be to further refine the technology to replicate and improve interaction.

Mike Farrell hopes the move forward will help build support for future research.

“The experiment changed scientific opinion. Ignition was almost always out of reach, [ou algo que só pode acontecer] 40 years into the future. The result in December was revealing.”

Back in Freiburg, Diamond Materials hopes to be able to invest more time in research. “About 20% of our staff is involved in research, and we are managing directors who are also physicists,” says Wild.

“Research at the level we produce is resource-intensive and we can’t neglect production. So we’ll likely continue to increase staff. After all, today’s research leads to tomorrow’s products.”

credit, Lawrence Livermore National Laboratory

Fusion at NIF is triggered by shooting laser beams at a small sphere filled with propellant.

Teams around the world scramble to build a working fusion power plant – using all sorts of methods. But it will take many years and billions of dollars of investment.

The NIF milestone last year is likely to give the industry a boost, says Farrell: “It may be easier to get funding from government and corporations now that we’ve shown that ignition is possible.”

This investment will be necessary to overcome the significant engineering challenges faced in building a power plant and, in particular, to find materials that can withstand the large amounts of energy released from the fusion process.

But Farrell is quick to point out how quickly progress can gain momentum once the initial breakthrough is made.

“After demonstrating first principles, as we just did, the engineers took it upon themselves to figure out how to do it iteratively.”

“Remember, the first flight by the Wright brothers was in 1903 and the first supersonic flight was in the 1950s. In 40 years or so, a lot of progress can be made.”

“Entrepreneur. Music enthusiast. Lifelong communicator. General coffee aficionado. Internet scholar.”

:strip_icc()/s04.video.glbimg.com/x720/11792055.jpg)

:strip_icc()/s03.video.glbimg.com/x720/11786998.jpg)