Most of the promising products are derived from carbon dioxide

3 min read

Environment

With information from RCGI – 08/16/2021

The chemical conversion of carbon dioxide is complicated, but it may be worth it.

[Imagem: Kelvin A. Pacheco et al. – 10.1016/j.jcou.2020.101391]

Use, do not store carbon dioxide

As carbon dioxide emissions in our society have become one of the main drivers of global warming, there has been a major effort to convert this carbon gas into fuels or other chemical compounds of industrial importance.

Not only can this capture carbon dioxide from the atmosphere, reducing the greenhouse effect, but also avoid additional fossil fuel burning, which releases more of it into the air, which is much more interesting than conventional carbon capture, sequestration and storage.

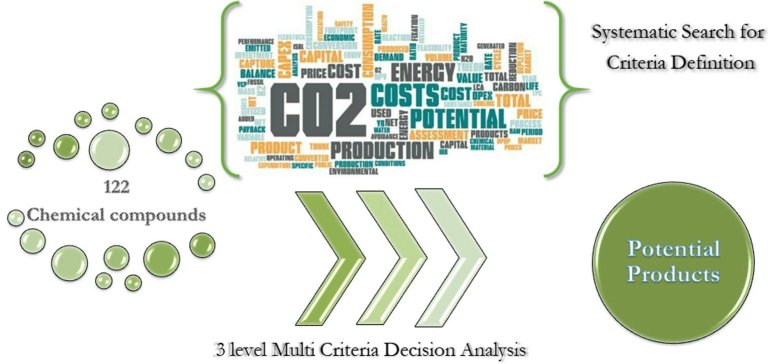

Because this new chemistry is not simple, one of the first challenges is to determine which compounds can be produced from CO2 and which ones have the greatest advantages in terms of technical feasibility, market potential and sustainability.

This was the work proposed by chemists from the University of the South Pacific Polytechnic School. “We have attempted to develop our own methodology to make selection a little more rigorous than what we found in the literature,” said researcher Kelvin Pacheco.

Chemical conversion of carbon dioxide

The researchers started with an initial scientist of 122 potential products, who were subjected to three selection steps. After defining the criteria and the best multi-criteria analysis tools, they underwent an assessment in which items such as the technological maturity of the product, the rate of CO2 utilization, growth projection and price were checked.

From the initial group of 122 people, 23 assays were selected for the first time, which were reduced to only the 8 most viable. Of these eight, the researchers identified the three most promising, both technically and commercially.

The analysis showed that dimethyl carbonate (DMC), acetic acid and dimethyl ester (DME) are the three CO-derived products with the greatest potential for development and the most promising for further studies.

“The chemical conversion of carbon dioxide to another chemical compound is an unfavorable reaction from an energy point of view. It is difficult to carry out,” explains Antonio Brisciani, a member of the team. “Another important aspect is that conversion, in addition to eliminating carbon dioxide emissions, must be commercially viable. There is no point in making the reaction feasible for a product that has no market or has less value.”

The methodologies analyzed by the team specifically sought to find products that met various criteria, given the difficulty of promoting interaction, marketability, and sustainability of the product.

Product Applications

The three carbon dioxide-derived products selected by the researchers have a significant environmental advantage. Dimethylcarbonate (DMC), for example, is currently produced mainly by the traditional route of methanol and phosgene, which presents several problems, the most important of which is the use of phosgene. It is a highly toxic gas that is generated as a byproduct of highly corrosive hydrochloric acid. Therefore, producing DMC from carbon dioxide instead of phosgene is a more environmentally friendly method.

Among the possible applications of DMC (dimethyl carbonate) is the manufacture of polycarbonate, a type of plastic capable of replacing glass, which is typically produced from the petrochemical industry. This process will make it possible to reduce 1730 tons of carbon dioxide for every 10,000 tons of polycarbonate produced. If the entire global production of polycarbonate used this process, there would be a reduction of about 450,000 tons of carbon dioxide per year. DMC can also be used as a solvent and fuel additive.

On the other hand, Dimethyl Ether (DME) gas has one of its possible applications replacing diesel as a fuel, which will open a large market. However, the question of price compared to petroleum products still needs to be resolved.

And the third product, acetic acid, is widely used in the chemical industry as a reagent. It is a precursor to vinyl acetate, used to make PVA, another type of plastic with many applications, such as adhesives.

condition: Multi-criteria decision analysis for screening CO2 conversion products

Authors: Kelvin A. Pacheco, Antonio E. Brisciani, Rita MB Alves

REVISTA: CO2 Usage Journal

Volume: 43, 101391

DOI: 10.1016 / j.jcou.2020.101391

Other news about:

More topics

“Entrepreneur. Music enthusiast. Lifelong communicator. General coffee aficionado. Internet scholar.”

:strip_icc()/s04.video.glbimg.com/x720/11792055.jpg)

:strip_icc()/s03.video.glbimg.com/x720/11786998.jpg)